|

|

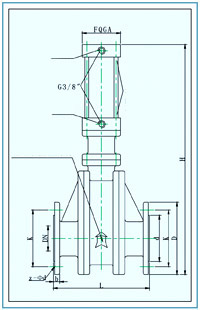

Z644Tc-10Q double-disc air-lock wear-resistant ceramic

discharge valve (Type AB)

(Warning: The products

are proprietary and patented, and unauthorized reproduction will

be prosecuted,Patent No:ZL02262821.5)

(Our company has passed ISO9001:2000.) |

|  The valves are mainly used

for opening and closing of charging and discharging of gas and

slag in dry ash system of power plant, and also applicable for

opening and closing of such media as wear and corrosion-resistant

fine dust, water, oil and vapor at tube edge in the industries

of mining, paper-making and petrochemical etc. PG double-disc

air-lock wear-resistant ceramic valve has the advantages of good

sealing property, high temperature resistance, strong wearability,

easy starting, no ash deposit and long service life. The valves are mainly used

for opening and closing of charging and discharging of gas and

slag in dry ash system of power plant, and also applicable for

opening and closing of such media as wear and corrosion-resistant

fine dust, water, oil and vapor at tube edge in the industries

of mining, paper-making and petrochemical etc. PG double-disc

air-lock wear-resistant ceramic valve has the advantages of good

sealing property, high temperature resistance, strong wearability,

easy starting, no ash deposit and long service life.

|

|

- The body of KR double-disc air-lock wear-resistant

ceramic valve is combined with cast steel, cast iron and wear-resistant

ceramics.

- Filler adopts fluorine rubber and carbon fiber

packing

- The nominal pressure of actuator is 0.4~0.6Mpa

and the nominal pressure of valve is 1Mpa

- Service temperature ≤250℃

- The size is DN50~DN200, customizable according

to user’s requirements

|

Installation instructions to bleeder valve:

Welcome to select the patented products of our company.

In order to prolong service life and improve operating efficiency,

this valve should be installed as vertical as possible, and if

the conditions do not allow the installation should be carried

out in 45°. For upside-down or horizontal installation, the idle

conveying time must be extended so as to avoid ash accumulation

in valve. In this valve the return signal adopts imported inductive

magnetic switch two-wire system, and the signal line can adapt

to both DC and AC via load. “Refer to the figure for installation

of signal line”

Operating instructions

1、Before installation this instruction should be

carefully read, and type, full bore and technical parameters of

the valve be checked.

2、After installation of valve welding flange is

forbidden to prevent from damaging the seal ring of valve. The

installation distance for valve reserved in pipelines shall be

appropriate, and gaskets shall be added on both sides of flange.

3、The centers of two pipelines shall be remained

coaxial with the center of valve full bore, and two sides of flange

shall be smooth so as to guarantee clamping and normal operation

of valve. |

Table of physical

dimension and coupling dimension of Z644Tc-10Q double-disc air-lock wear-resistant ceramic

discharge valve (Type AB), and model of matched actuator

| Sizemm |

coupling dimension |

physical dimension and matched actuator(mm) |

| DN |

D |

D1 |

b |

Z-d |

L |

H |

FQGA |

| 50 |

160 |

125 |

15 |

4-Ф18 |

200 |

464 |

80﹡65 |

| 65 |

180 |

145 |

15 |

4-Ф18 |

220 |

516 |

80﹡80 |

| 80 |

195 |

160 |

16 |

8-Ф18 |

250 |

632 |

100﹡95 |

| 100 |

215 |

180 |

16 |

8-Ф18 |

280 |

725 |

125﹡115 |

| 125 |

245 |

210 |

18 |

8-Ф18 |

320 |

807 |

125﹡140 |

| 150 |

280 |

240 |

18 |

8-Ф22 |

360 |

905 |

160﹡165 |

| 200 |

335 |

295 |

20 |

8-Ф22 |

334 |

1120 |

200﹡220 |

|

| |

|