Installation

and adjustment

In

pursuit of optimal operation, during installation the control

lever for valve location should be installed on top (most ideal)

or side of the conveying line. The sealing of valve is realized

via the superimposition between valve disk and valve seat. Therefore,

the valve support should be independent of the conveying line

and not withstand force from pipeline devices. In addition, measures

should be taken to prevent the expansion of pipelines for heating

from applying force on the valve.

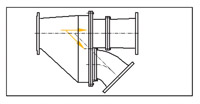

The installation of changeover valve should be able to prevent

air pressure in valve closing branch from

acting

on the sealing surface of valve disk, as shown in the figure.

Operation and application:

The

transposition of valve disk should be carried out on condition

that the system stops operation (no pressure), however, the valve

should not be manipulated as the system is conveying materials,

because:

(1)The valve disk is under pipeline pressure, the wear will accelerate

if the valve disk is moved under load;

(2)Movement of the valve disk under load will produce a load higher

than normal torque causing failure of the valve disk to operate

normally;

(3)If transposition of the valve disk is performed during conveyance

of materials by the system, the accumulation of materials will

be created due to loss of pressure in some pipeline of the valve.

As a result, abnormalities such as pipe jam, pressure fluctuation

and overload of air compressor, etc. will be caused when this

pipeline is enabled once more next time. Before transposition

of the valve disk the conveying pipe should be cleared up and

blown off. When transposition is made by manipulating the valve

after stop of the system, it is quite favorable to rotate the

control lever for valve location for several times first, and

then to transpose the valve disk to required position, in such

way the valve seat is cleaned and the life of valve is extended

as well.

During outage of conveying system, rotating the control lever

for valve location is in favor of removing accumulating contaminants

such as dust and condensed water, etc. so as to prolong the life

of valve seat. 。

Automatic opening and closing of the pneumatic changeover valve

are accomplished by valve used pneumatic device (cylinder). After

power source and air source are connected, the cylinder drives

transposition of valve core to make the valve stop at proper location.